Steps to take a product to manufacture

Before embarking on the Manufacturing Development process, it is important that you have already completed early phases of designing, prototyping and testing to ensure that the prototype meets your requirements. You can view more information on the design process here.

We can review your idea free of charge and give you the best options to commercialise it, under confidentiality agreement.

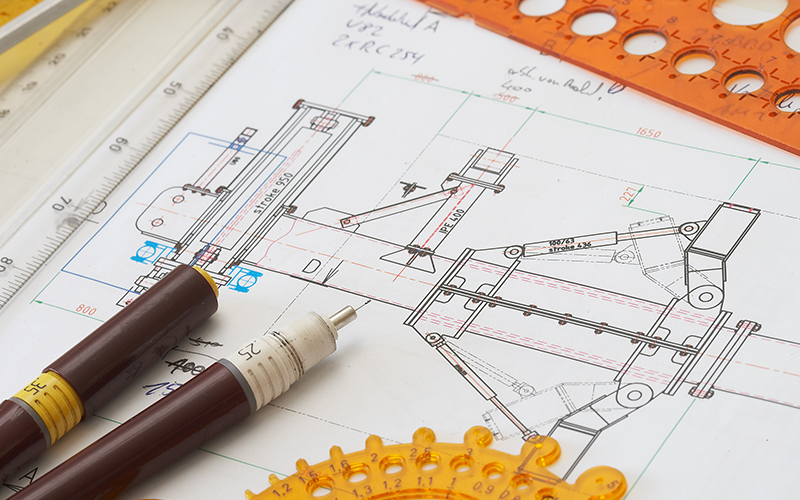

Detail Design

In Detail Design, we review component manufacturing processes and materials. We may consult with manufacturers about specific equipment limitations.

For example, when reviewing injection moulded parts, we would consider draft angles, gate locations and surface finishes.

At the end of Detail Design you receive a report outlining the checks and changes we have implemented.

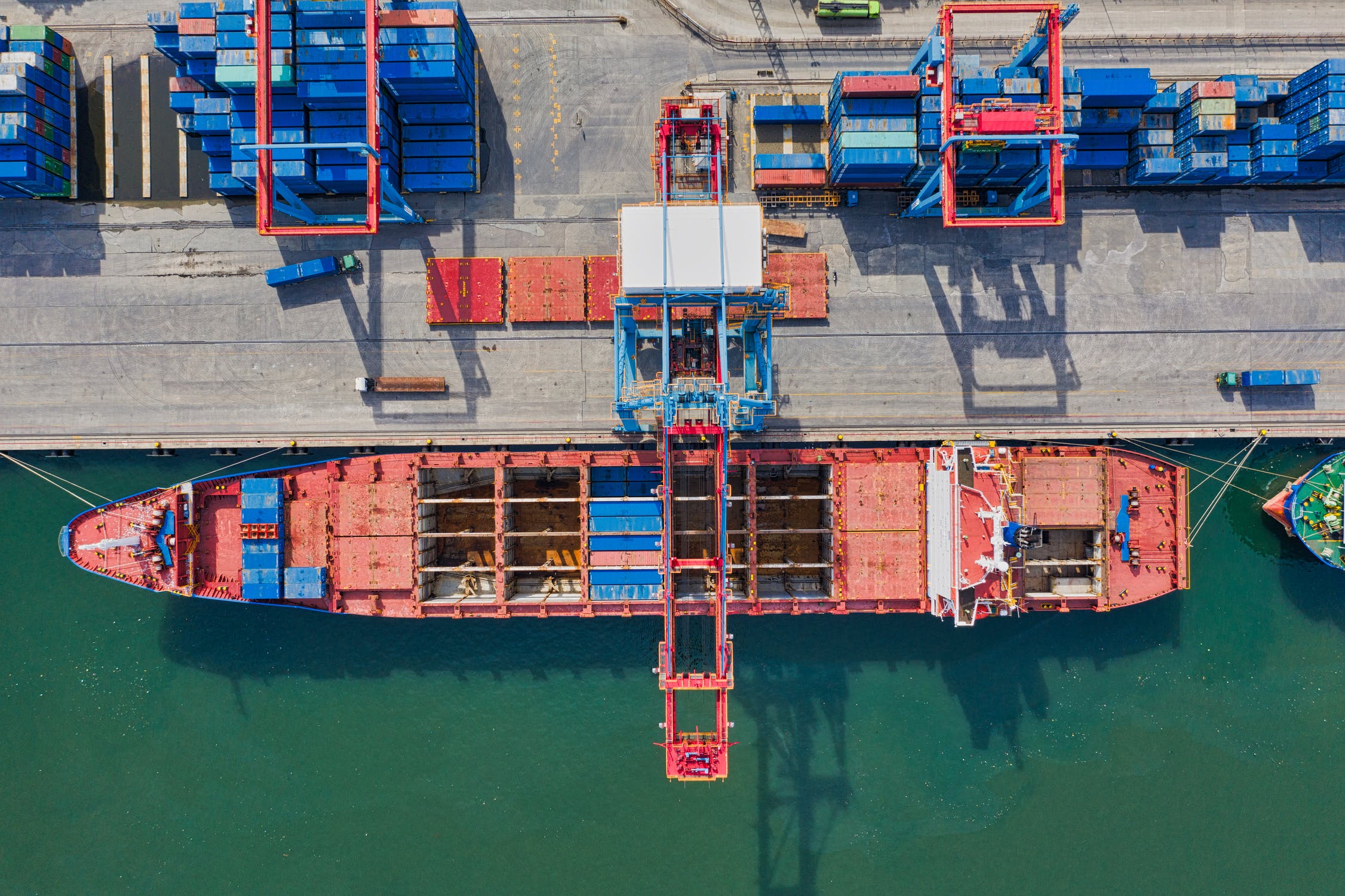

Manufacturing support

Innovate can help you deal directly with suppliers and manufacturers about costs and production timelines. You can distribute through your own retail outlet, or a distribution centre and our manufacturing division, Innovate Make can help you. There is the option of using more than one method to make money from your idea, for example through crowdfunding in order to fund production.

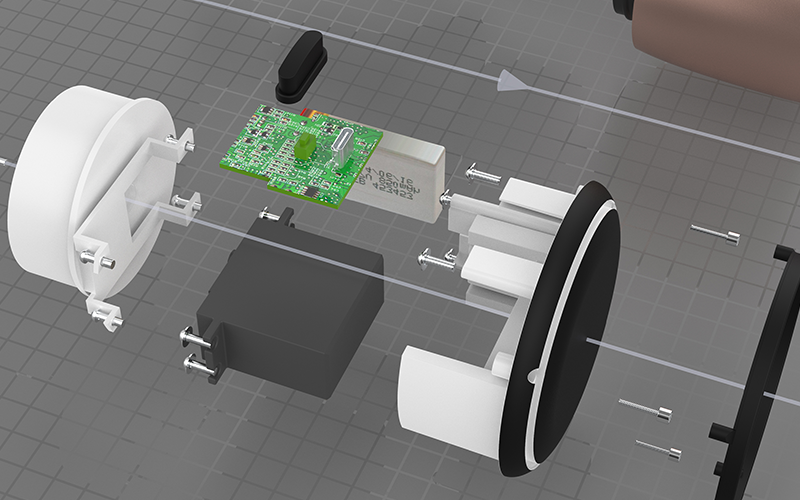

Final Design Prototype

This will look and function as if it was the final product, but the component parts will most likely be made using different manufacturing method processes and materials than in mass production.

It is not a “golden sample”, but can be used in a similar way, to help manufacturers understand how the product should be produced. Because we have already worked extensively on the design, the prototype can often be lower cost than previous prototypes. To find out more about the prototyping process click here.

Why build a Final Design Prototype?

You are about to manufacturer larger quantities of your product. It is important to verify the final design before you pay for tooling. Failing to do this could be a costly mistake.

Request for Quotation Pack (RFQ)

A Request for Quotation Pack includes the files needed to request price estimates from manufacturers. The files can also be used for manufacture. It usually comprises of:

- Engineering Drawings

- 3D and 2D files

- BOM (Bill of Materials)

- GA views (General Assembly Views)

Cost Model Analysis

In cost model analysis, we use the RFQ Pack that we created to collect production cost estimates and add further costs to give an estimated RRP (Recommended Retail Price). This can then be used to understand how much money is required to start production and what the potential profits might be. This might include:

- Production Costs

- Freight and Duty Costs

- Margins and RRP

What next?

You have now turned an idea into a product, next you need to turn your project into a business. Talk to us about the business support we offer here