What is the Maker Movement?

The Maker Movement, where millions of makers take huge risk in starting their own businesses devoted to producing and selling self-made products. In recent years, it has gathered increasing momentum with a rise in the number of makers employing the do-it-yourself attitude. Although the maker era might not be upon us yet, this is a point in time that could have a transformative impact on the innovation industry. Modern technology is now making it easier than ever to cut out the need to license products. This allows makers to create and distribute products themselves.

Makers are a diverse bunch of people. In a world where everyone is an entrepreneur, it’s hard work getting others excited about funding your project. Money goes to those who know how to attract attention. However, the American Association for the Advancement of Science said “3-D printers have become cheaper and more capable […] they are opening up a new era of do-it-yourself manufacturing”. But what does this mean for today’s makers? Here’s an example to help explain.

3-D Printing vs Injection Moulding

Let’s say a maker wants to make 100 computer mouse prototypes. In theory, you could self-manufacture a computer mouse via injection moulding. This is the shaping of plastic by injecting heated material into a mould. The maker could also use 3-D printing. This is the process of making a physical object from a three-dimensional digital model. Usually, injection moulding is used to produce reliable parts in high volume. Unfortunately, tooling must be made before the manufacturing process begins. This results in a very expensive start-up cost which - for a computer mouse - might cost over £20,000. But remember, the maker only wants 100 prototypes.

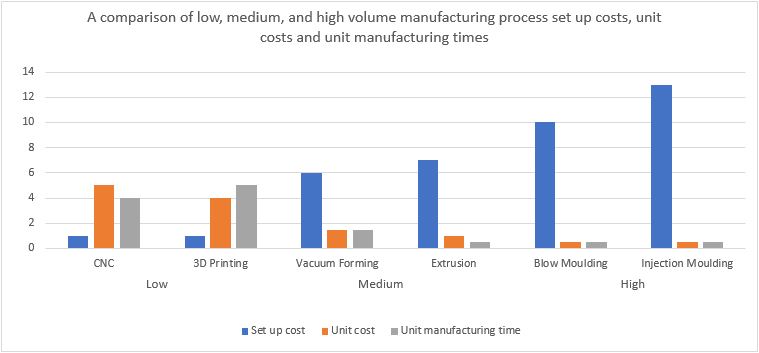

Therefore, 3-D printing would be a cheaper alternative as it requires a lower start-up cost (approximately a tenth of the cost) to make 100 prototypes. The table below shows that injection moulding would be more cost-effective in the long-run. However, for the first 100 prototypes, 3-D printing would be more cost-effective for an inventor (with little experience) looking to get their new product to market. Please note that unit cost will vary depending on quantity and complexity of design. Components can be designed to suit specific processes and quantities.

Overall, this growing shift will continue to affect the economy. Consumers will be given more choice and manufacturing will become increasingly decentralised. This will likely have big implications on large retailers.

Even though the maker movement has only just begun, Innovate wonder where this creative movement will take us next?

If you have a new product idea, Innovate can help - simply submit your idea via our online submission form.